Description

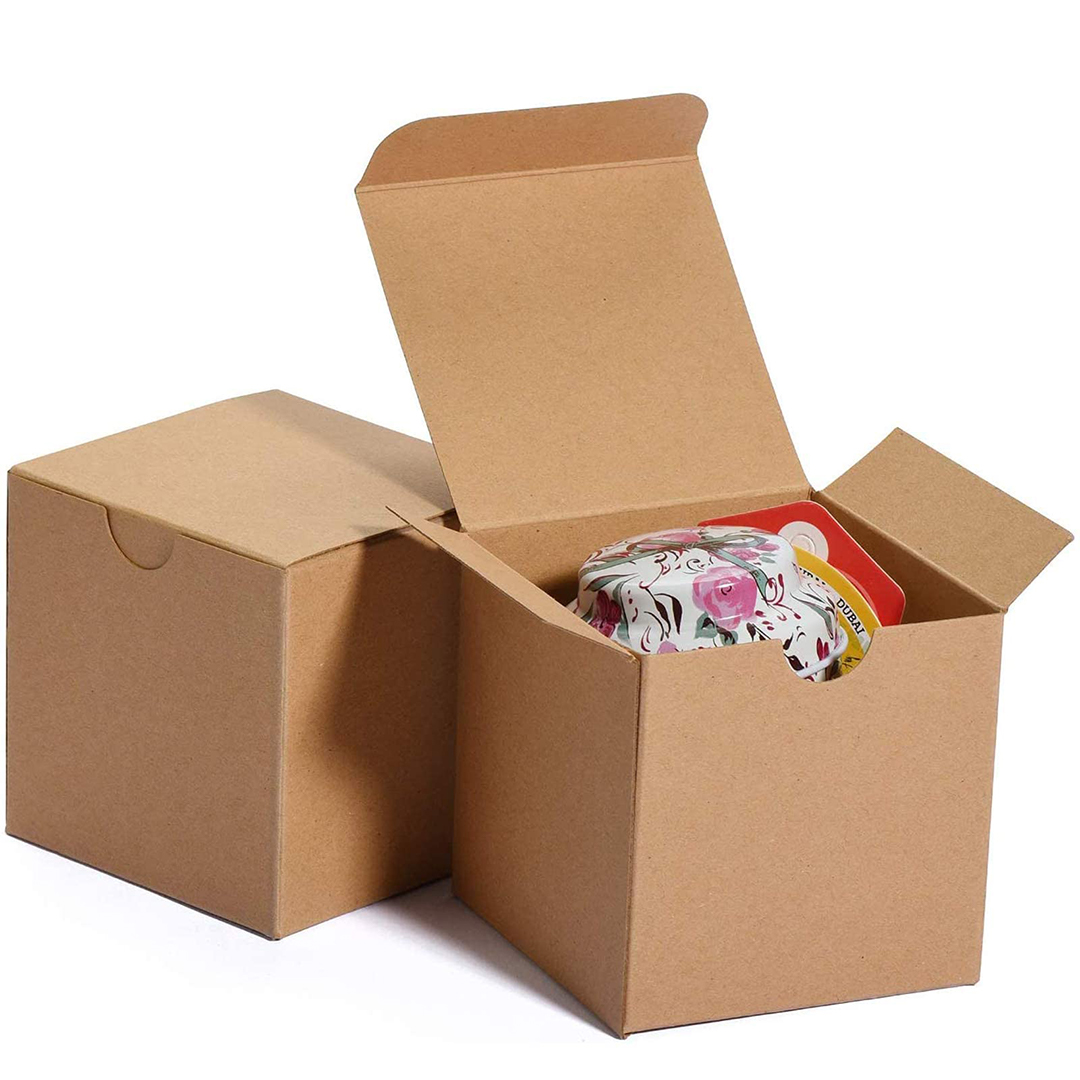

Kraft Industrial Parts Boxes For Safe Sorting

We at Kraft Box Pack offer Kraft Industrial Parts Boxes at wholesale prices for teams that need clean storage, quick picking, and safer transit for small hardware. Many buyers pair them with Kraft Bulk Shipping Crates when they want the same kraft look across inner packs and outer shipment protection. These boxes are built to keep parts separated, reduce mix-ups, and protect edges when cartons are moved on racks, carts, and pallets. If you handle screws, fittings, bearings, clamps, or mixed hardware, a stable box shape helps the contents stay organized from packing to delivery.

Industrial parts usually travel through multiple hands, so the box has to stay square and close neatly without the flaps bending out of line. A right-size box reduces extra space, which lowers shifting and keeps metal parts from rubbing into corners. Clear labeling zones also matter because fast picking depends on readable SKU and bin details. When you need consistent results across repeat orders, a steady dieline and predictable board strength reduce day-to-day packing problems.

How These Boxes Reduce Mix Ups In Order Picking

Kraft Industrial Parts Boxes reduce mix-ups by giving each part type a dedicated space and a consistent labeling face. When the same size and layout is used across a line, staff learns the pack pattern quickly. This improves speed during picking and reduces wrong-part returns. The box also keeps loose items contained, which helps maintain count accuracy for small pieces.

Another reason they help is visibility and control. You can use dividers, trays, or smaller inner cartons to separate similar parts that look alike. If you store multiple SKUs in one shipment carton, stable inner boxes help prevent spills when cartons tilt. This keeps the packing bench cleaner and saves time during restocking.

Warehouse Handling Details That Matter Every Day

- Firm corners that stay square under stacking pressure

- Right-size depth to reduce part movement inside the box

- Clean faces for barcode labels and short identifiers

- Options for dividers to keep similar items separated

- Stable closure so small parts do not spill in transit

Clear Steps For Setting Up Parts Storage Systems

- Group parts by size, weight, and surface sensitivity

- Choose box depth that prevents items from jumping during movement

- Add dividers when similar parts must stay separated

- Set one label position for every SKU to speed up picking

- Test stacking on racks to confirm the box keeps its shape

| Feature Focus | Details | Material Options | Finishing Choices | Add-ons & Features | Usage Application |

|---|---|---|---|---|---|

| Sorting Control | Helps separate mixed hardware in storage | Kraft wrap over rigid board | Matte, Gloss | Divider trays | Small parts organization |

| Shape Stability | Keeps corners firm during stacking | Heavy kraft board options | Matte | Reinforced base | Rack storage and staging |

| Label Clarity | Clear faces for barcodes and short IDs | Kraft board with smooth wrap | Matte | Label panel area | Picking and inventory |

| Spill Prevention | Closure stays steady during movement | Scored kraft construction | Gloss | Locking flap option | Transit handling |

| Repeat Consistency | Same dieline helps reorders match | Standard kraft builds | Spot UV | Batch control points | Ongoing supply cycles |

Kraft Product Boxes For Industrial Parts And Tools

Kraft product boxes support industrial parts storage when the goal is clean organization, predictable packing speed, and fewer transit issues across bulk runs. Many teams use Kraft Industrial Packaging to keep a consistent packaging system for tools, fittings, machine spares, and repair kits. The main advantage is control, because you can plan one outer format and adapt the inside with dividers or inserts. This helps when parts vary by project but the warehouse needs one repeatable box style.

A practical way to choose a structure is to start with the weight and edges of the items. Sharp or heavy parts need firmer walls and better corner support. Smaller parts need better containment and separation so counts stay accurate. This is where the idea of a Kraft Storage Box becomes useful, because the box is not only for shipping, it is also for storage on shelves and in bins where teams open and close packs repeatedly.

How To Choose A Kraft Storage Box For Shelves

A Kraft Storage Box works best when the footprint fits shelf depth and the height matches how items are accessed during picking. If the box is too tall, staff has to dig, and parts can spill. If it is too wide, cartons waste shelf space and cause unstable stacking. A balanced size supports clean rows and faster restocking. It also keeps labels facing outward for quick scanning.

Many industrial teams also ask if “paper boxes with lids” can hold heavy items. The answer depends on board strength, closure style, and how tight the fit is. Paper boxes with lids can work well when the board is strong and the lid closes without bending. For mixed kits, the divider idea is similar to Gift Boxes with dividers, where separation prevents rubbing and keeps the layout consistent.

Practical Benefits For Daily Packing And Storage

- Predictable sizes that stack cleanly on warehouse shelves

- Divider support to separate similar-looking metal pieces

- Stable walls that resist corner crush during handling

- Clean surfaces for printing and label readability

- Better control of small-part counts in storage

Quick Checks For Bulk Warehouse Box Repeat Runs

- Confirm part weight and edges to match board strength

- Choose a shelf-friendly footprint for clean row storage

- Add divider layout for mixed kits and repair bundles

- Test lid closure so it does not bow or snag

- Validate carton stacking to reduce corner pressure marks

| Feature Focus | Details | Material Options | Finishing Choices | Add-ons & Features | Usage Application |

|---|---|---|---|---|---|

| Shelf Fit | Footprint supports clean rack rows | Kraft board builds | Matte | Size control system | Warehouse shelving |

| Mixed Kit Layout | Separation reduces rubbing and mix-ups | Dividers, inner trays | Matte | Modular dividers | Repair and service kits |

| Weight Readiness | Stronger walls reduce crush risk | Thick board options | Gloss | Reinforced corners | Metal spares packing |

| Lid Control | Lids stay aligned during repeated use | Scored lid designs | Matte | Lock tabs option | Parts access routines |

| Label Zones | Consistent label face improves speed | Smooth wrap areas | Spot UV | Barcode panel | Inventory workflows |

Finishes And Print Options For Durable Marking

Industrial packaging still needs clear identification, even when the focus is storage and shipment rather than gifting. For later-stage planning and consistent reorders, Kraft Packaging Wholesale supports fixed sizing, readable print placement, and steady build quality across repeat runs. Clear markings help reduce wrong-part issues, especially when cartons move between warehouses, job sites, and service teams. A clean print zone on the lid and front panel also makes scanning faster, which matters when many cartons look similar on a rack.

Along with printing, surface protection is a practical choice. Coating options like Gloss, Matte, and Spot UV can be selected based on handling exposure and labeling needs. Matte helps reduce glare under warehouse lights and can keep the kraft tone calm. Gloss can make printed areas look stronger and help surfaces wipe cleaner when cartons pick up dust. Spot UV can highlight a key identifier area without covering the entire pack. Design and shipping, custom sizes and styles, fast turnaround times, and high-quality material and printing options can be arranged to match tight project schedules and repeat ordering cycles.

Which Coatings Help Reduce Marks During Transit

Coatings help reduce rub marks when cartons move inside master cartons or slide on shelves. Matte finishes can hide small scuffs better under everyday lighting. Gloss finishes can reduce surface drag and make some marks less visible, depending on the handling pattern. Spot UV is usually used for a focused highlight area, such as a logo or key label zone, and it can help an identifier stand out without heavy ink coverage.

People also ask whether coatings used in kraft food packaging are relevant for industrial cartons. The short answer is that barrier ideas exist, but industrial needs are different. Industrial cartons usually focus on scuff control, label clarity, and dust resistance rather than direct food contact. If your parts include oily components, a protective coating can also help keep the outer surface cleaner during storage and transit.

Details That Keep Boxes Cleaner During Transit

- Coating choice matched to rubbing and shelf movement

- Print zones kept away from folds and high-stress edges

- Strong corners to reduce pressure dents in stacked cartons

- Divider layouts to limit internal movement and rubbing

- Consistent finish settings to keep reorders matching

Clear Steps For Keeping Print And Labels Legible

- Set one primary label face for every SKU and carton size

- Keep key text away from hinge lines and corner folds

- Choose Matte, Gloss, or Spot UV based on handling exposure

- Test cartons in master packs to confirm rub patterns

- Lock the same print and finish settings for reorders