Description

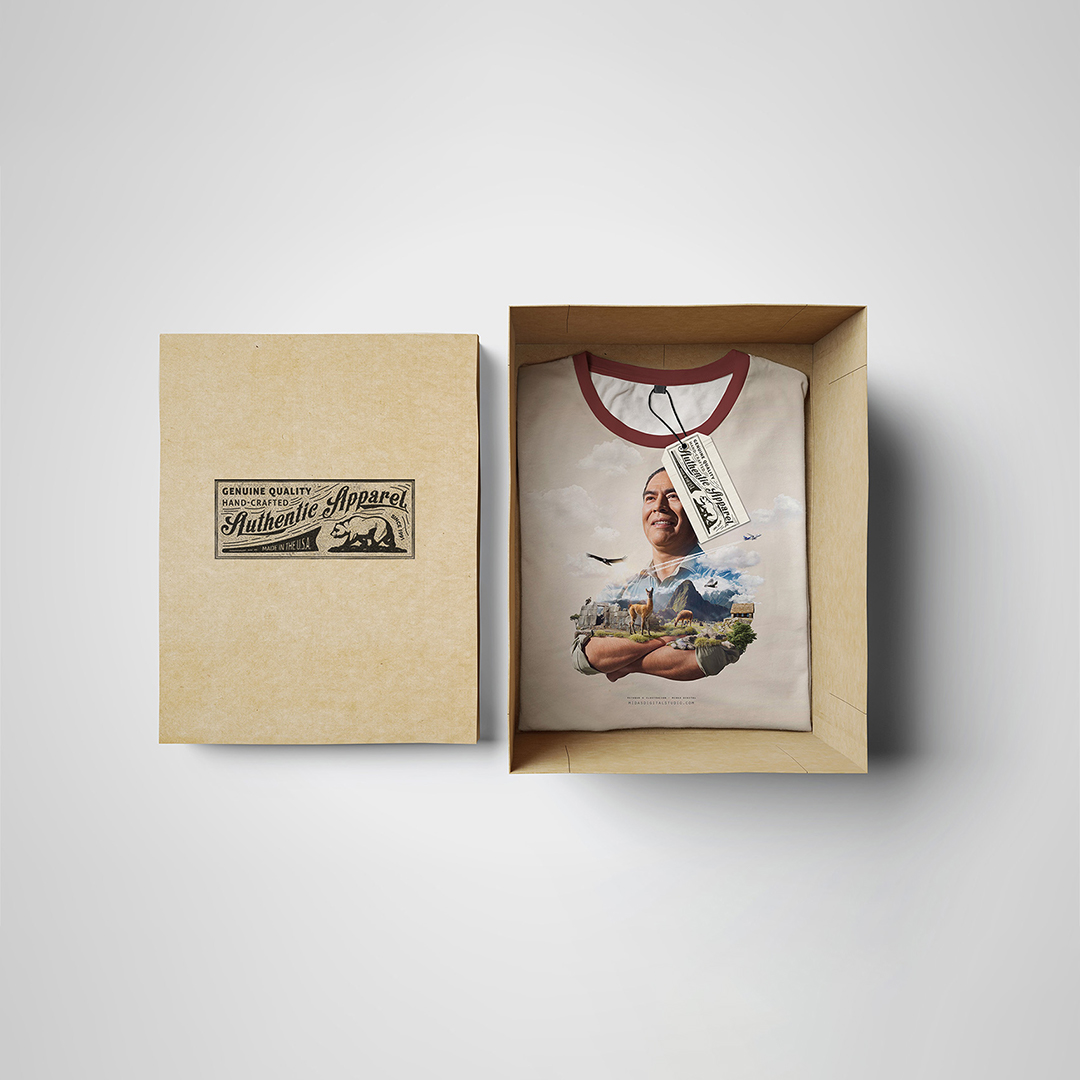

Premium Kraft T Shirt Boxes For Folded Apparel

Kraft T Shirt Boxes help apparel brands keep folded shirts flat, clean, and well-presented from packing to delivery. These boxes are often chosen when you need a steady shape, neat edges, and a smooth unboxing that looks good on camera. Many stores use them for online orders, gifting, and seasonal launches where a simple kraft look supports the product without visual noise. If you are comparing packaging boxes wholesale options, focus on fit, lid alignment, and surface wear because those details show up fast during handling.

For bulk packing, the box should hold its line when stacked and moved in cartons. In many apparel programs, Kraft Apparel Packaging Boxes are used alongside shirt boxes so branding and sizing stay consistent across different clothing items. The inside space should match the fold style so the shirt does not slide or bunch at corners. When the fit is controlled, the lid closes cleanly and the front edge stays even. This makes the box more reliable for repeat packing routines and repeat orders.

Why A Clean Lid Line Matters On Shirt Gift Boxes

A clean lid line keeps the box looking neat in photos and in hand. When the lid sits flat, the front edge looks straight and the corners look sharper. This matters for apparel because customers notice small details in the first few seconds. A stable lid also prevents rubbing at edges during transit. Less rub means fewer marks and fewer re-packs.

Key Things Buyers Compare For Shirt Packaging

- Lid closes flat and stays aligned after handling

- Inner space supports the fold style without shifting

- Corners stay clean during stacking and carton movement

- Surface finish helps reduce light scuffs and rub marks

- Branding stays centered on lid and front-facing panels

Steps To Plan A Simple Folded Shirt Pack

- Choose the fold style you use most often

- Measure the folded width, length, and stack height

- Add light clearance for tissue, cards, or a sleeve

- Confirm the lid closes without pushing the shirt

- Test carton stacking so corners stay protected

| Feature Focus | Details | Material Options | Finishing Choices | Add-ons And Features | Usage Application |

|---|---|---|---|---|---|

| Fold Support | Keeps tees flat with controlled inner space | Kraft wrap over rigid board | Matte, Gloss | Inner card support | Folded shirt packing |

| Lid Alignment | Helps front edge stay even in stacks | Rigid board builds | Matte | Edge wrap control | Store orders |

| Corner Strength | Reduces corner softening during transit | Thick board options | Anti-scratch coat | Reinforced base | Shipping cartons |

| Branding Zones | Centers artwork on lid and side panels | Kraft + print layer | Spot UV | Foil accent option | Brand presentation |

| Packing Flow | Supports fast packing without re-folding | Fixed dieline sizes | Matte, Gloss | Tissue space planning | Fulfillment use |

| Reorder Match | Keeps the same look across repeat runs | Standard wrap settings | Any selected finish | QC references | Ongoing supply |

T Shirt Boxes Wholesale For Bulk Branding Runs

When you order T shirt boxes wholesale, the main goal is consistency across every unit in the run. The size must stay stable, the lid must sit flat, and the print must stay centered so stacked boxes look uniform. Many buyers also compare kraft boxes with lids because the lid style affects how quickly teams pack and how well the box holds shape in storage. A reliable build reduces rework, lowers damage in transit, and keeps unboxing neat for customers and content creators.

For brands that sell multiple apparel items, Kraft Apparel Boxes often provide a matching family of options so your tees, shirts, and sets share the same kraft tone and print feel. This helps when you restock or run seasonal campaigns because packaging stays consistent across product lines. Some buyers also compare Shirt boxes Dollar Tree listings for basic storage, but wholesale apparel packaging usually needs stronger walls and cleaner print alignment. That difference becomes clear when you stack boxes, ship in cartons, and handle larger volumes.

How To Choose Depth And Fit For Folded T Shirts

Depth should match the folded stack height, not just the shirt size. A box that is too shallow presses the fold and can leave creases. A box that is too deep lets the shirt slide and shift. Controlled clearance keeps the shirt centered and supports a clean opening view. It also helps the lid close without strain.

What Helps Bulk Runs Stay Consistent

- Fixed footprint to keep carton layouts predictable

- Depth planned for tissue, cards, and folded stack height

- Strong corners to reduce transit wear in cartons

- Print placement locked for repeat runs

- Finish chosen for handling and scuff control

Steps Buyers Use Before Approving A Bulk Run

- Confirm folded measurements with tissue included

- Choose board strength based on stack and shipping needs

- Approve dieline so reorders match without changes

- Confirm print zones stay away from folds and edges

- Test stacking to check lid lines and corner stability

| Feature Focus | Details | Material Options | Finishing Choices | Add-ons And Features | Usage Application |

|---|---|---|---|---|---|

| Bulk Repeatability | Supports repeat runs with matching results | Rigid board + kraft wrap | Matte, Gloss | Fixed dieline | Wholesale supply |

| Fit Control | Keeps folded tees centered and stable | Insert cards, dividers | Matte | Tissue allowance | Apparel orders |

| Lid Behavior | Reduces gaps and keeps lid flat | Scored board builds | Matte | Lid edge control | Gift packing |

| Surface Wear | Limits rub marks from handling | Protective coat layers | Anti-scratch | Corner buffers | Shipping cycles |

| Brand Consistency | Maintains the same look across lines | Kraft wraps + print | Spot UV | Foil accent option | Store branding |

| Carton Efficiency | Improves stacking and reduces shifting | Standard footprints | Any finish | Sleeve option | Fulfillment |

Printing And Coatings For Clean Brand Display

Printing needs to stay readable on kraft, especially on lid panels that appear in photos and unboxing clips. Matte can reduce glare under lights, gloss can increase shine on printed areas, and Spot UV can highlight a logo without changing the full surface. These coating options are often selected based on how the box will be handled and how often it will be shipped. Many apparel brands also plan design and shipping, custom sizes and styles, fast turnaround times, and high-quality material and printing options to match campaign timelines and release calendars.

For long-term consistency, Kraft Boxes Wholesale is used by many buyers who want repeat ordering with stable dielines, controlled print placement, and consistent finish settings across reorders. Print layouts should avoid heavy coverage near folds and edges to reduce cracking or rub on high-touch areas. If you ship frequently, protective coatings can reduce visible marks at corners. If you focus on gifting and store presentation, Spot UV can create contrast on a logo area while keeping the overall kraft tone calm.

How Matte Gloss And Spot UV Reduce Wear Marks

Matte finishes reduce glare and can hide small rub marks better under normal lighting. Gloss finishes reflect more light and can make printed colors appear stronger. Spot UV adds a controlled shine to selected areas such as a logo mark. This can help brand elements stand out while keeping most of the surface subtle. The right choice depends on how the boxes will be handled.

Printing Choices That Keep Kraft Looking Clean

- Centered lid graphics for a balanced top view

- Clear margins away from folds and hinge lines

- Matte finish for lower glare under lights

- Gloss finish for stronger printed contrast

- Spot UV for controlled logo highlights

Steps To Keep Print Results Consistent In Reorders

- Confirm the lid as the primary branding panel

- Keep key text away from edges and fold lines

- Choose Matte, Gloss, or Spot UV based on handling needs

- Review proofs under normal and bright lighting

- Lock finish settings for consistent repeat batches

| Feature Focus | Details | Material Options | Finishing Choices | Add-ons And Features | Usage Application |

|---|---|---|---|---|---|

| Glare Control | Keeps photos clean under studio lights | Kraft wraps | Matte | Soft-touch option | Content shoots |

| Logo Contrast | Highlights brand marks in select areas | Kraft + print layer | Spot UV | Emboss option | Brand display |

| Surface Protection | Reduces rub on corners and edges | Protective coat | Anti-scratch | Corner buffers | Shipping |

| Color Visibility | Improves print clarity on kraft | Underlayer options | Gloss | Foil accent option | Gift packs |

| Repeat Matching | Keeps batches consistent over time | Fixed proof references | Any finish | QC checkpoints | Reorders |

| Premium Feel | Supports a neat hand feel | Quality wraps | Matte, Gloss | Inner liner option | Store packing |