Description

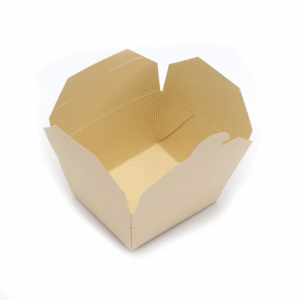

Kraft Recycled Kraft Boxes For Daily Use In Retail

Kraft recycled kraft boxes are often selected when brands want a steady outer look and a practical pack that holds shape during routine handling. Many campaigns pair them with other kraft packaging lines such as Kraft Insulated Cold Boxes when the goal is to keep a consistent kraft theme across multiple product lines. The recycled kraft surface reads clean in photos and stays easy to stack on shelves or in storage racks. When you are planning Kraft recycled kraft boxes for sale, the main details usually come down to board strength, lid fit, and how the box behaves after repeated opening and closing.

Kraft recycled kraft boxes bulk orders also benefit from stable sizing because small changes show quickly when units are arranged in rows. A close fit reduces inner movement, which helps keep corners cleaner during shipping and reduces rubbing inside the pack. Many buyers also prefer short, repeatable packing steps, so staff can pack kits without adjusting the layout each time. If your products ship often, surface protection and carton layout matter because edges and corners pick up wear first.

What Makes Recycled Kraft Packs Feel Reliable

Kraft recycled kraft boxes are recycled-paper based packs designed to hold products with a firm structure while keeping the outside look simple and consistent. The most reliable builds use steady scoring, clean folds, and a base that stays square under light stacking. When the lid meets the same edge each time, the box keeps a neat front line, which matters for display rows and unboxing content.

People also ask why recycled kraft feels different from other finishes. The answer is that recycled kraft tones can soften print colors, so spacing and contrast should be planned with care. A well-planned layout keeps logos readable without heavy ink coverage. When the inner layout is stable, the unboxing looks organized and the box remains usable for storage after the first opening.

Key Details People Look For In Recycled Kits Today

- Firm walls that keep the box square during stacking

- Lid fit that closes neatly without gaps at the front edge

- Inner space that reduces movement during transit

- Print layout that stays readable on kraft tones

- Surface protection that limits rub marks at corners

Steps To Set Sizes And Artwork For Bulk Runs

- Measure the product with any wrap or padding included

- Add controlled clearance so packing stays quick and clean

- Choose the box depth based on inserts or layered packing

- Place key branding on the lid with balanced margins

- Approve a proof under normal lighting for kraft contrast

| Feature Focus | Details | Material Options | Finishing Choices | Add-ons And Features | Usage Application |

|---|---|---|---|---|---|

| Recycled Build Control | Stable folds and edges for repeat handling | Recycled kraft wrap, rigid board core | Matte, Gloss | Reinforced base panel | Retail display, storage |

| Lid Fit Consistency | Neat close line for shelf rows | Board scoring options | Matte, Spot UV | Edge wrap control | Subscription drops |

| Print Readability | Layout stays clear on kraft tones | Kraft with optional underlayer | Gloss, Spot UV | Foil accent option | Brand kits |

| Transit Wear Reduction | Less rubbing at corners in cartons | Stronger board choices | Anti-scratch coating | Corner buffers | Shipping cycles |

Kraft Recycled Kraft Boxes Wholesale Buying Guide

Kraft Recycled Kraft Boxes Wholesale Buying Guide choices usually start with repeatability because the same pack is often reordered for new seasons and new product releases. Many buyers use Kraft Industrial Packaging for heavier-duty programs and keep recycled kraft boxes for retail-facing presentation that still needs strength. The wholesale planning stage works best when size, depth, and finish are locked early, because late changes can affect lid fit, corner stability, and print placement across a run. If you are comparing Kraft boxes wholesale options, focus on how consistent the structure stays when units are stacked and moved in bulk.

Kraft recycled kraft boxes price is usually shaped by size, board thickness, print coverage, and the finish level chosen for handling conditions. Many brands also choose Gloss, Matte, or Spot UV based on where the boxes will be used and how often they will be touched. You can also request custom sizes and styles, Design and shipping, fast turnaround times, and high-quality material and printing options, while keeping the packaging details clear and practical. For bulk buying, the most useful goal is a setup that makes reorders predictable and keeps the same look across campaigns.

How To Compare Kraft Boxes Wholesale For Kits

Kraft boxes wholesale comparisons get easier when you check the same set of points on each option. Start with the base strength and how square the box stays under light stacking. Then check lid fit, because small gaps can show in photos and look uneven in display rows. If the box will ship often, confirm how the corners hold up inside master cartons, since rubbing marks can appear before the box reaches the recipient.

People also ask how to reduce surprises in bulk runs. A clear answer is to keep one approved dieline and avoid changing the footprint between campaigns. When you keep the same size and only adjust artwork, packing routines stay stable and carton layouts remain efficient. That is often the practical difference between smooth reorders and reorders that require new packing steps.

Points That Help Bulk Buyers Make Clean Decisions

- One approved dieline that supports repeat runs

- Stable lid fit that stays consistent across batches

- Sizing that improves carton stacking and reduces shifting

- Finish choice matched to handling and transit exposure

- Print placement centered on lid and front-facing panels

Steps To Lock A Repeat Ready Bulk Plan

- Confirm final dimensions using real products and inserts

- Choose board strength based on weight and stacking needs

- Select Matte, Gloss, or Spot UV based on handling level

- Approve proof placement on lid and side panels

- Confirm carton packing so corners rub less in transit

| Feature Focus | Details | Material Options | Finishing Choices | Add-ons And Features | Usage Application |

|---|---|---|---|---|---|

| Wholesale Repeatability | Keeps reorders consistent across seasons | Recycled kraft wrap options | Matte, Gloss | Fixed dieline setup | Ongoing campaigns |

| Cost Drivers | Size, depth, print, finish, inserts | Board thickness ranges | Spot UV | Insert support | Bulk planning |

| Handling Protection | Reduces visible wear during movement | Stronger board builds | Anti-scratch coating | Corner buffers | Warehousing, shipping |

| Print Matching | Maintains layout consistency on reprints | Kraft with optional underlayer | Gloss, Matte | Foil accent option | Retail presentation |

Kraft Paper Boxes With Lids For Food Packing Needs

Kraft paper boxes for food are usually planned around a clean lid fit and a stable base so the pack holds shape while moving between prep areas and delivery cartons. Many brands rely on Custom Kraft Boxes when they want consistent sizes, steady print placement, and repeatable builds for recycled kraft programs. Kraft boxes with lids are often chosen because the lid helps keep the pack neat in handling and supports stacking in storage. When you also need a clear first look, Kraft Boxes with Window styles can be planned with a controlled cut-out and stable inner placement so the product stays aligned behind the window line.

Kraft recycled kraft boxes for sale can include lid styles that suit different packing routines, including simple tuck fits and rigid lid designs, depending on how the box will be used. A practical approach is to match the lid type to handling conditions, then select a finish that helps reduce rub marks during transit. Recycled kraft tones can also support minimal branding, while still allowing strong contrast designs when the artwork is planned around spacing. If your program includes food items, keeping the inside layout stable and the outer structure firm helps the pack stay presentable through the first handling cycle.

Where Kraft Boxes With Window Help Product Views

Kraft Boxes with Window options help when visibility improves clarity for the buyer or supports quick photo content. The window cut should be placed to frame the product cleanly while keeping enough border support around the cut so the box remains firm. A stable inner layout is important because if the product slides, it can shift away from the window and the presentation looks uneven.

People often ask how to keep window packs stable during shipping. A clear answer is to reduce empty space inside, add insert support when needed, and keep carton stacking tight so boxes move less. When the box stays square and the product stays centered, the window view remains clean and consistent across a run.

Details That Keep Lids And Windows Looking Neat

- Lid fit that stays even along the front edge

- Window border support that keeps the box firm

- Inner space that limits movement during transit

- Finish choice that reduces rub at corners and edges

- Print layout that stays readable on kraft tones

Steps To Plan Lids And Window Layouts Cleanly

- Choose the lid style based on handling and stacking needs

- Set the window size to frame the product without excess opening

- Keep controlled clearance so the product stays centered

- Select a finish that matches transit and daily handling exposure

- Confirm carton layout so units shift less during movement