Description

Chemical Safe Kraft Boxes For Secure Storage Use

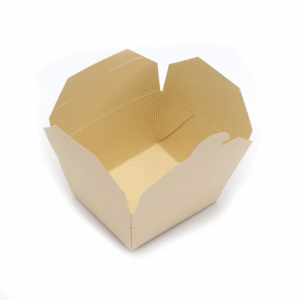

Kraft Chemical Safe Boxes are used when teams need controlled storage and shipping for sealed chemical items, lab supplies, and cleaning products. Many operations that already rely on Kraft Heavy Duty Storage Boxes for warehousing prefer similar board strength when the shipment needs extra care around leaks, pressure, and handling. These boxes are planned to stay square in cartons and reduce corner damage during movement. They also help keep outer labels readable so handlers can sort units without repeated re-checking. Kraft Box Pack offers Kraft Chemical Safe Boxes at wholesale prices for repeat orders where consistency matters.

For real-world use, the inside layout is just as important as the outer build. Kraft chemical safe boxes sizes should be chosen around the actual bottle, jar, or sealed pouch dimensions, including padding and dividers. A close fit reduces sliding, which lowers the chance of rubbing and edge wear inside the pack. When a kit includes multiple units, divider panels help keep items separated and centered. The goal is simple handling, stable stacking, and fewer transit marks on corners.

What Makes A Kraft Box Chemical Safe In Transit

A chemical-safe pack is built around containment and control rather than display. It supports sealed items with steady walls, a stable base, and inner spacing that limits movement. The safest results come from matching the box size to the item, adding dividers or inserts when needed, and keeping labels clear on the outer panels so handlers can identify the load quickly.

In practical workflows, teams also look at how the box behaves in cartons. Units that stack evenly reduce shifting, and that lowers surface rub during transit. If items are sensitive to pressure, the pack depth is planned so the top does not press down on caps. These details support safer handling without making the packing routine slow.

Key Handling Points For Safer Chemical Packing

- Use inserts or dividers to limit contact between sealed units

- Keep a close fit to reduce sliding inside the box

- Place labels on flat panels away from folds and edges

- Plan carton stacking so corners do not rub in movement

- Keep pack depth balanced so caps are not under pressure

Steps To Set Up A Repeatable Packing Routine Fast

- Measure sealed items with padding included

- Choose a box size that reduces empty space

- Add dividers for multi-item kits to prevent rubbing

- Confirm cartons stack evenly without lid pressure

- Lock the same dieline for repeat wholesale runs

| Feature Focus | Details | Material Options | Finish Options | Add-ons & Features | Common Use |

|---|---|---|---|---|---|

| Containment Support | Reduces shifting for sealed items | Rigid board with kraft wrap | Matte, Gloss | Divider panels | Lab kits |

| Corner Stability | Helps the pack stay square in cartons | Thicker board options | Protective coat | Reinforced base | Shipping cycles |

| Label Visibility | Keeps handling info readable | Kraft wrap with print layers | Spot UV for logo only | Clear label zone | Warehouse sorting |

| Insert Fit | Controls movement inside the pack | Card inserts, foam supports | Matte interior feel | Lift tabs | Multi-item kits |

| Stack Control | Supports even stacking in cartons | Rigid board builds | Anti-scuff option | Corner buffers | Bulk dispatch |

Kraft Chemical Safe Boxes Review For Bulk Buyers

Bulk buyers usually judge chemical-safe packaging by repeatability, handling control, and how well the outer panels stay readable after transit. In many industrial programs, Kraft Industrial Packaging is used to keep related kraft formats consistent across storage and shipping needs. A useful “Kraft chemical safe boxes review” focuses on real points like carton stacking, corner wear, and whether the inside layout prevents bottles from shifting. If a box looks neat only on day one but rubs quickly in cartons, it creates extra work and inconsistent presentation on delivery.

Kraft chemical safe boxes price typically depends on size, board strength, printing coverage, and inner components like dividers or inserts. For packaging boxes wholesale planning, a fixed dieline helps control costs across reorders because only artwork changes between runs. Teams also compare chemical-safe boxes with other kraft formats, such as Kraft Bags and Kraft Window Bags, when the shipment is lighter and the risk level is lower. For food programs, food safe boxes are a separate category with different handling goals, and they should not be treated as the same as chemical storage packs.

How To Choose Liners For Chemical Contact Safety

Liners and inner wraps are chosen to keep the inside surface clean and reduce transfer marks from sealed units. The key is to match the liner choice to the product type and packing routine, then keep the fit stable so items do not rub along inner walls. When items are sensitive to heat or pressure, the pack depth is planned so caps and seals do not sit under load during stacking.

For multi-unit kits, dividers reduce contact points and keep items centered. If the shipment includes printed cards or manuals, a flat pocket area can separate paper from sealed units. These layout choices make handling smoother and help keep the box interior tidy after transit, especially in repeat programs.

Common Questions Teams Ask Before Bulk Orders

- Will the box size reduce movement for sealed containers

- Do dividers keep units separated during carton stacking

- Is the outer print placed away from fold stress zones

- Will the finish reduce corner rub during handling

- Can the same dieline support repeat runs consistently

Steps That Help Stabilize Cartons In Shipping

- Keep unit footprints consistent for neat carton stacking

- Use corner buffers when cartons are tightly packed

- Avoid overfilling cartons that press down on caps

- Separate paper inserts from sealed items inside the box

- Confirm label zones remain readable after transit handling

| Feature Focus | Details | Material Options | Finish Options | Add-ons & Features | Common Use |

|---|---|---|---|---|---|

| Bulk Repeatability | Stable results across reorders | Fixed board grades | Matte, Gloss | QC match points | Wholesale cycles |

| Divider Control | Reduces bottle-to-bottle contact | Card dividers | Matte interior | Grid layouts | Multi-unit kits |

| Print Durability | Keeps labels readable in handling | Kraft print layers | Protective coat | Clear label zones | Sorting |

| Carton Fit | Supports stable stacking and movement | Rigid board builds | Anti-scuff option | Corner support | Transit loads |

| Cost Drivers | Size and inserts impact pricing | Board thickness options | Spot UV limited | Insert choices | Budget planning |

Sizes Pricing And Ordering For Chemical Safe Packs

Ordering works best when the box size is planned around sealed items, padding, and the carton layout you already use in dispatch. For consistent reorders and steady lead times, Kraft Boxes Wholesale supports custom sizes and styles that keep dielines stable while artwork updates remain simple. Kraft chemical safe boxes sizes can be set for single units, multi-unit divider layouts, or mixed kits that include paperwork and samples. A close fit helps reduce internal rubbing, which supports cleaner delivery and fewer marks on corners. This also helps warehouses stack and store units with less shifting.

Kraft chemical safe boxes price is easier to manage when you lock one footprint and adjust only depth where needed. Finishing options can include Matte, Gloss, and Spot UV, and these choices can be matched to handling exposure rather than appearance alone. Orders can also include design and shipping options, fast turnaround times for scheduled runs, and high-quality material and printing options for clear labeling. If you also run other kraft programs, it can help to separate categories clearly, such as Kraft Bread Bags and Kraft paper Resealable Bags for food items, while chemical-safe boxes remain dedicated to sealed chemical storage and shipping control.

How Do Coatings Help Labels Stay Clear In Shipping

Coatings protect outer panels from light abrasion so labels stay readable after cartons move through handling steps. Matte finishes reduce glare under warehouse lighting, gloss finishes can increase sharpness for printed text, and Spot UV can highlight a logo area while leaving label zones clean. The best choice is the one that keeps handling text readable and reduces corner rub during transit.

A coating also supports repeat programs because surface feel stays more consistent across batches. When cartons are tightly packed, corners can rub during movement, and a protective finish helps reduce visible wear. If labeling is a priority, keep print away from folds, place key text on flat panels, and use finishes that match real handling conditions.

Finish Options That Support Clear Product Labels

- Matte finish helps reduce glare on handling text

- Gloss finish can sharpen printed label visibility

- Spot UV can highlight brand marks without crowding labels

- Protective coats help reduce rub on corners and edges

- Consistent finish settings support stable reorders

Order Steps For Reorders And Campaign Schedules

- Confirm item measurements with padding and dividers included

- Choose a footprint that stacks neatly in master cartons

- Lock print zones for labels on flat panels

- Select Matte, Gloss, or Spot UV based on handling exposure

- Keep the same dieline for repeat wholesale ordering